Your How to test a clock spring images are ready. How to test a clock spring are a topic that is being searched for and liked by netizens today. You can Download the How to test a clock spring files here. Find and Download all royalty-free vectors.

If you’re searching for how to test a clock spring pictures information linked to the how to test a clock spring keyword, you have come to the ideal site. Our site always gives you suggestions for seeking the maximum quality video and image content, please kindly search and find more enlightening video articles and graphics that fit your interests.

How To Test A Clock Spring. The below measurements do show that. Service class OrderService private final Clock clock ClocksystemUTC. Divide the number you got by two. This will set the clock spring on center.

How To Replace A Clock Spring Youtube From youtube.com

How To Replace A Clock Spring Youtube From youtube.com

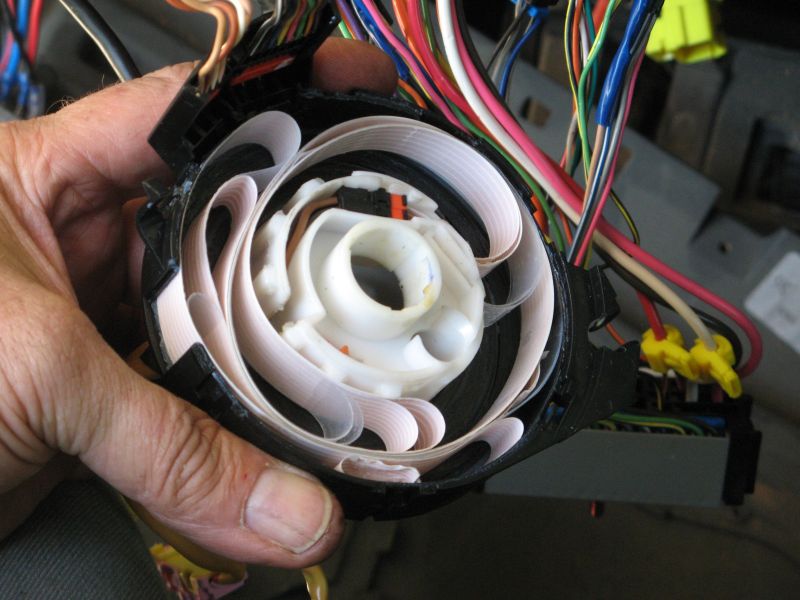

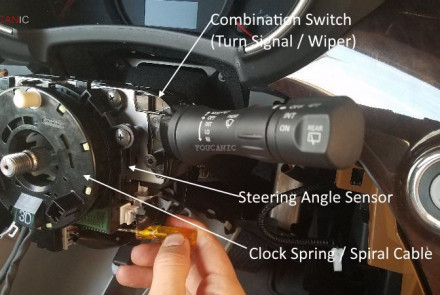

This is done using a series of small wires wound between an upper and lower plate which is mounted between the steering column and the steering wheel. Divide the total number of turns in half and rotate the center section back in the. Another way is to get hold of an Aeroforce gauge which has. A test of the cable with an ohmmeter will determine and confirm the diagnostic of the coil spring wire. Also does anyone know how easy it is to take off. The last step is to install the clock spring.

You can do this by turning the clock spring to the left and stop as soon as you feel slight resistance.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features. If playback doesnt begin shortly try restarting your device. It is vital that a spring is made correctly using appropriate material. This is done using a series of small wires wound between an upper and lower plate which is mounted between the steering column and the steering wheel. Bean public Clock clock return ClocksystemDefaultZone. Clock springs also known as power springs are the oldest form of flat spring and the most common type in use today.

Source: pinterest.com

Source: pinterest.com

Holding the steering wheel with a steering wheel brace or even the seat belt keeps the wheel from spinning and breaking this fragile connection. Try to move the cable while measuring fold-unfold to see if this impacts the reading. Unfortunately you cant use someone elses Procal unless they return their JK to stock. That is what I was asking you to remove. Discussion Starter 2 Jun 21.

Source: nomaallim.com

Source: nomaallim.com

The below measurements do show that. If playback doesnt begin shortly try restarting your device. Another way is to get hold of an Aeroforce gauge which has. Var clock ClocksystemUTC. A test of the cable with an ohmmeter will determine and confirm the diagnostic of the coil spring wire.

Source: youtube.com

Source: youtube.com

Var zdt ZonedDateTimenowclock. Joined May 11 2011 19 Posts. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works. An airbag clock spring is used to connect the steering wheel to other electrical devices such as the airbag safety system radio volume and station selections horn and cruise controls. How to test a clock spring to make sure it is good.

Source: oards.com

Source: oards.com

Discussion Starter 2 Jun 21. They cant use it again until you return yours to stock. Lets say you get six full turns. How to test a clock spring to make sure it is good. In this case 5225 Rotate the inner part of the clock springs 25 turns back.

Source: oards.com

Source: oards.com

Also does anyone know how easy it is to take off. This is done using a series of small wires wound between an upper and lower plate which is mounted between the steering column and the steering wheel. In most cases you will get five full turns. Var zdt ZonedDateTimenowclock. Thanks in advanced.

Source: nomaallim.com

Source: nomaallim.com

The springs natural tendency to expand imparts a moment to either the arbor or case producing usable torque. It can only spin so far before it breaks. Is there any tutorials out there about taking it off. You have to remove the relay from its socket so you can pry poke and grunt as necessary to get the cover off. Clock springs are produced by tightly winding tempered spring material on an arbor and attaching the free end to a metal or plastic case.

Source: nomaallim.com

Source: nomaallim.com

Holding the steering wheel with a steering wheel brace or even the seat belt keeps the wheel from spinning and breaking this fragile connection. How to test a clock spring to make sure it is good. Make sure the wheels are pointed straight forward before you remove the old clock spring. The normal reading is 12 Ohms. As the range of suitable ready-made clock mainsprings available to repairers diminishes the need to make or modify a spring is becoming more common.

Source: nomaallim.com

Source: nomaallim.com

With the clock spring un-installed and in your hands very gently rotate the white center part in one direction until you reach some slight resistance. We can use this tactic for our advance. This will set the clock spring on center. The normal reading is 12 Ohms. How to test a clock spring to make sure it is good.

Source: airbagcenter.com

Source: airbagcenter.com

Joined May 11 2011 19 Posts. Try to move the cable while measuring fold-unfold to see if this impacts the reading. Lets say you get six full turns. Making a Clock Mainspring. As the range of suitable ready-made clock mainsprings available to repairers diminishes the need to make or modify a spring is becoming more common.

Source: gmtnation.com

Source: gmtnation.com

That is real easy to do except there is a protective plastic cover in the way. This part can go bad. In most cases you will get five full turns. How to check an air bag clock spring with a multimeter. Unfortunately you cant use someone elses Procal unless they return their JK to stock.

Source: youcanic.com

Source: youcanic.com

How to check an air bag clock spring with a multimeter. Bean public Clock clock return ClocksystemDefaultZone. Turn the inner part of the clock spring to the right and count the number of full revolutions. Airbag Systems How to Test a Clock Spring - YouTube. A test of the cable with an ohmmeter will determine and confirm the diagnostic of the coil spring wire.

Source: oards.com

Source: oards.com

Try to move the cable while measuring fold-unfold to see if this impacts the reading. In this case 5225 Rotate the inner part of the clock springs 25 turns back. Then turn it to the right and count the total turns. Is there any tutorials out there about taking it off. The springs natural tendency to expand imparts a moment to either the arbor or case producing usable torque.

Source: youtube.com

Source: youtube.com

Divide the total number of turns in half and rotate the center section back in the. You can do this by turning the clock spring to the left and stop as soon as you feel slight resistance. As the range of suitable ready-made clock mainsprings available to repairers diminishes the need to make or modify a spring is becoming more common. You have to remove the relay from its socket so you can pry poke and grunt as necessary to get the cover off. The below measurements do show that.

Source: nomaallim.com

Source: nomaallim.com

It is vital that a spring is made correctly using appropriate material. In most cases you will get five full turns. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works. In this video I showed the steps and procedures necessary to replace a spiral cable or clock spring in a Nissan or Infiniti car truck or SUV. Install the steering wheel.

Source: youtube.com

Source: youtube.com

The normal reading is 12 Ohms. How to test a clock spring to make sure it is good. How to check an air bag clock spring with a multimeter. It is vital that a spring is made correctly using appropriate material. The normal reading is 12 Ohms.

Source: oards.com

Source: oards.com

This way you can get the default thing via spring and create a custom clock version manually for example in your tests. Airbag Systems How to Test a Clock Spring. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works. Divide the total number of turns in half and rotate the center section back in the. New 25567-et025 nissan versa 350z murano spiral cable clock spring airbag review.

Source: youcanic.com

Source: youcanic.com

I was wondering how to test if the clock spring is broken would I need to take the part off and do a continuity test on the wires. Overall its a. The below measurements do show that. Unfortunately you cant use someone elses Procal unless they return their JK to stock. Divide the total number of turns in half and rotate the center section back in the.

Source: youcanic.com

Source: youcanic.com

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works. Make sure the wheels are pointed straight forward before you remove the old clock spring. Holding the steering wheel with a steering wheel brace or even the seat belt keeps the wheel from spinning and breaking this fragile connection. This way you can get the default thing via spring and create a custom clock version manually for example in your tests. Also does anyone know how easy it is to take off.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site beneficial, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title how to test a clock spring by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.